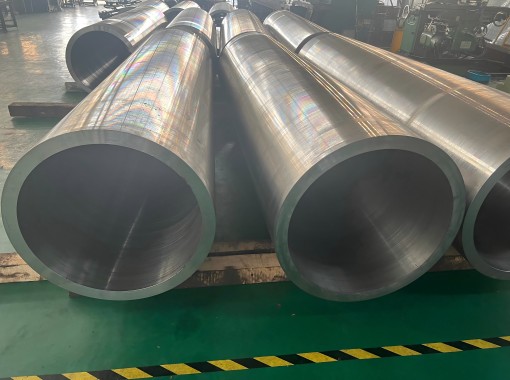

ST52 Turning Surface Tube

ST52 Turning Surface Tube

ST52 Turning Surface Tube is a high-quality,hot-finished seamless steel tube made from ST52 structural steel, designed for precision machining and mechanical applications. Its seamless construction ensures reliability in critical mechanical applications.The “ST52” refers to the steel grade, which is a high-strength, low-alloy steel.

Advantages

1. Superior Strength & Durability: High Tensile Strength– Handles heavy loads without deformation;Excellent Toughness – Resists impact and fatigue, ideal for dynamic applications;No Welded Seams – Eliminates weak points, ensuring uniform strength.

2. Excellent Machinability: Smooth Surface Finish;Consistent Material Structure;Compatible with CNC & Lathe Turning – Achieves tight tolerances.

3. Cost-Effective Performance: ST52 Turning Surface Tube is more affordable than Alloy Steels – Balances strength and cost (vs. 4140, 4340).Reduced Machining Costs – Requires less finishing work compared to welded tubes.

4. Corrosion Resistance: The steel composition provides moderate resistance to corrosion, especially when properly maintained.

5. Seamless Construction: The seamless nature of the tube ensures uniformity and reliability in high-pressure applications.

6. Versatility: Suitable for a wide range of applications, including hydraulic cylinders, pneumatic cylinders, and precision engineering components.

Material Composition

| Element | Composition |

|---|---|

| Carbon (C) | ≤ 0.22% |

| Silicon (Si) | ≤ 0.55% |

| Manganese (Mn) | 1.00 – 1.60% |

| Phosphorus (P) | ≤ 0.025% |

| Sulfur (S) | ≤ 0.025% |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength | ≥ 355 MPa |

| Tensile Strength | 490-630 MPa |

| Elongation | ≥ 22% |

Delivery Condition: SR,BK, BK+S, GBK, NBK

ID Size : 20mm – 1500mm

Length: max 16m

Type: Seamless, Hot Rolled, Cold Rolled, Cold Drawn

Straightness: ≤ 0.5/1000

Roughness: as request

Tolerance INT: as request

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or Plywood case

Delivery Conditions

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation.Appropriate further processing allows a certain degree of cold forming(e.g.bending,expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process.Subject to appropriate processing conditionsthe increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Contact Us

Interested in our products? Contact us for quotes, partnerships, or technical support!