DIN 2391 ST52 Seamless Cold Drawn Tube

DIN 2391 ST52 Seamless Cold Drawn Tube

DIN 2391 ST52 Seamless Cold Drawn Tube is a high-precision steel tube manufactured through cold drawing, ensuring excellent dimensional accuracy, smooth surface finish, and superior mechanical properties. It is widely used in mechanical engineering, hydraulic systems, automotive components, and general structural applications.

Advantages

1. Superior Dimensional Accuracy & Tight Tolerances: Cold drawing ensures high precision in outer diameter and wall thickness.Reduces the need for additional machining, saving time and cost.

2. Excellent Surface Finish: DIN 2391 ST52 seamless cold drawn tube’s smooth, scale-free surface due to cold working and possible subsequent polishing.Ideal for applications requiring high wear resistance.

3. High Strength: ST52 steel offers good mechanical properties, including high tensile strength and toughness.

4. Corrosion Resistance: The steel composition provides moderate resistance to corrosion, especially when properly maintained.

5. Seamless Construction: The seamless nature of the tube ensures uniformity and reliability in high-pressure applications.

6. Versatility: Suitable for a wide range of applications, including hydraulic cylinders, pneumatic cylinders, and precision engineering components.

Material Composition

| Element | Composition |

|---|---|

| Carbon (C) | ≤ 0.22% |

| Silicon (Si) | ≤ 0.55% |

| Manganese (Mn) | 1.00 -1.60% |

| Phosphorus (P) | ≤ 0.025% |

| Sulfur (S) | ≤ 0.025% |

| Iron (Fe) | Balance |

Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength | ≥ 355 MPa |

| Tensile Strength | 490-630 MPa |

| Elongation | ≥ 22% |

Delivery Conditions

| Designation | Symbol | Description |

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation.Appropriate further processing allows a certain degree of cold forming(e.g.bending,expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process.Subject to appropriate processing conditionsthe increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Delivery Condition: SR,BK, BK+S, GBK, NBK

ID Size : 20mm – 1500mm

Length: max 16m

Type: Seamless, Cold Drawn

Straightness: ≤ 0.5/1000

Roughness: Ra < 1.6

Tolerance EXT: DIN2391, EN10305, GB/T 1619,GOST 8731,GOST 1050,GOST4543

Tolerance INT: as per request

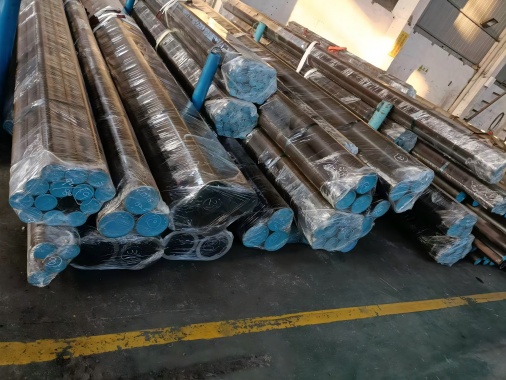

Protection: Anti-rust oil on inside and outside surface, plastic caps in both ends.

Packing: Bundle with steel strip and PE sheet or Plywood case

Contact Us

Interested in our products? Contact us for quotes, partnerships, or technical support!